News Details

13

2024

-

12

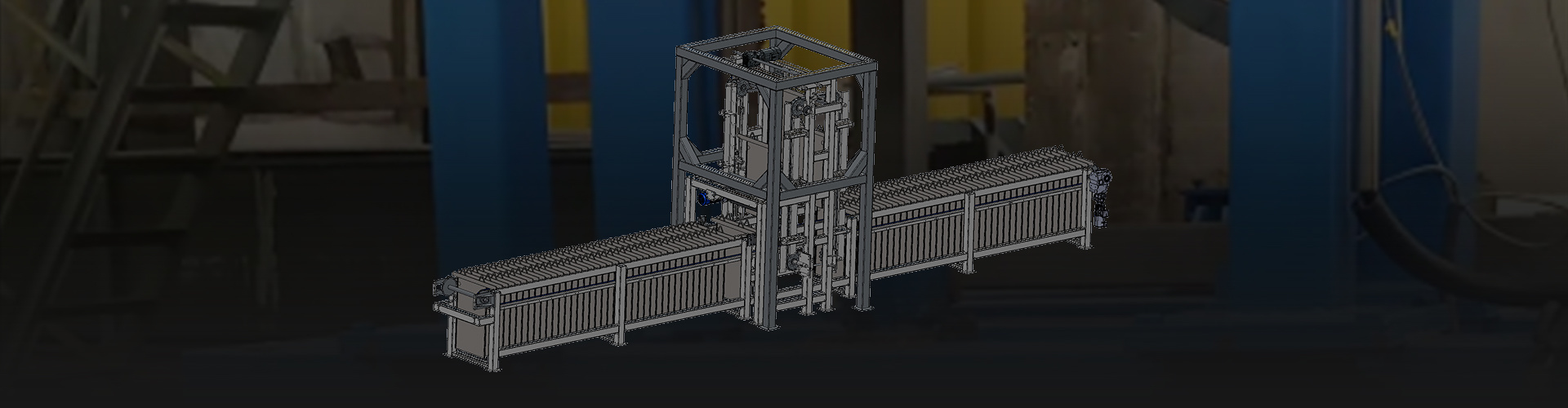

High-efficiency board brushing machine

The high-efficiency board brushing machine is a device used in the circuit board manufacturing process

The high-efficiency board cleaning machine is a device used in the circuit board manufacturing process, mainly for cleaning and removing dirt, grease, and other impurities from the surface of PCBs for subsequent processing. Here are some main functions and features of the high-efficiency board cleaning machine:

Automatic control of the cleaning process: The high-efficiency board cleaning machine can automatically control the cleaning process and display the cleaning status in real-time. Operators can set the time and temperature for each stage of cleaning, rinsing, and drying, and the machine automatically completes each cleaning step, ensuring the continuity of the cleaning process without the need for operator supervision, thus improving production efficiency.

Process parameter settings: The process parameters of the water cleaning machine include solvent ratio, solvent temperature, cleaning time, rinsing time, rinsing water volume, rinsing times, cleanliness detection, drying temperature, drying time, cooling time, spraying pressure, and solvent reflux delay, etc. These parameters can be set according to product requirements to ensure cleaning quality.

Operating steps: The general steps for operating the high-efficiency board cleaning machine include preparation work, preparing the PCB to be cleaned, setting parameters, placing the PCB, starting the machine, cleaning treatment, draining, drying, inspection, and shutting down the machine.

Technical parameters: Different models of high-efficiency board cleaning machines have different technical parameters, such as production board size, board thickness capacity, transfer height, transfer speed, brush roller speed, brush roller oscillation, measurement accuracy deviation, water pressure and circulating water volume, water consumption, machine power supply, and machine weight, etc.

Outstanding features: Some high-efficiency board cleaning machines have features such as the machine's production line width can be automatically set on the touch screen, stable machine structure, specifically designed for cleaning solder balls, flux residues, and scratches, anti-static imported brown bristle brushes, suitable for PCBA boards with edges, thorough cleaning of PCBs in all directions without dead angles, and driven by high-quality electronic speed-regulating motors.

Environmental protection and efficiency: The high-efficiency board cleaning machine is suitable for traditional cleaning water, does not require manual contact with cleaning agents, and the cleaning process is sealed, reducing the emission of chemical odors into the workshop while improving cleaning efficiency and consistency.

Intelligent functions: Some high-efficiency board cleaning machines are equipped with intelligent functions, such as automatic brushing, automatic grinding, quick brush replacement, and no zeroing, which further enhance the convenience and efficiency of operating the board cleaning machine.

In summary, the high-efficiency board cleaning machine improves the efficiency and quality of PCB cleaning through automated and intelligent operations, making it an indispensable device in the circuit board manufacturing process.

More news

2025-12-25